In viscous forces and consequently quantifies the relative importance of these two types of forces for given flow conditions.

The concept was introduced by [3]

Reynolds numbers frequently arise when performing dynamic similitude between different experimental cases.

They are also used to characterize different flow regimes, such as vortices and other flow instabilities.

Contents |

[edit] Definition

Reynolds number can be defined for a number of different situations where a fluid is in relative motion to a surface.inertial forces defined in the classical way’.

where:

is the mean velocity of the object relative to the fluid (SI units: m/s)

is the mean velocity of the object relative to the fluid (SI units: m/s) is a characteristic linear dimension, (travelled length of the fluid; hydraulic diameter when dealing with river systems) (m)

is a characteristic linear dimension, (travelled length of the fluid; hydraulic diameter when dealing with river systems) (m) is the fluid (Pa·s or N·s/m² or kg/(m·s))

is the fluid (Pa·s or N·s/m² or kg/(m·s)) is the kinematic viscosity (

is the kinematic viscosity ( ) (m²/s)

) (m²/s) is the density of the fluid (kg/m³).

is the density of the fluid (kg/m³).

Note that multiplying the Reynolds number by  yields

yields  , which is the ratio of the inertial forces to the viscous forces.[5] It could also be considered the ratio of the total momentum transfer to the molecular momentum transfer.

, which is the ratio of the inertial forces to the viscous forces.[5] It could also be considered the ratio of the total momentum transfer to the molecular momentum transfer.

[edit] Flow in pipe

For flow in a pipe or tube, the Reynolds number is generally defined as:[6]

where:

is the hydraulic diameter of the pipe; its characteristic travelled length,

is the hydraulic diameter of the pipe; its characteristic travelled length,  , (m).

, (m). is the volumetric flow rate (m3/s).

is the volumetric flow rate (m3/s). is the pipe cross-sectional area (m²).

is the pipe cross-sectional area (m²). is the mean velocity of the fluid (SI units: m/s).

is the mean velocity of the fluid (SI units: m/s). is the fluid (Pa·s or N·s/m² or kg/(m·s)).

is the fluid (Pa·s or N·s/m² or kg/(m·s)). is the kinematic viscosity (

is the kinematic viscosity ( (m²/s).

(m²/s). is the density of the fluid (kg/m³).

is the density of the fluid (kg/m³).

For shapes such as squares, rectangular or annular ducts where the height and width are comparable, the characteristic dimension for internal flow situations is taken to be the hydraulic diameter,  , defined as:

, defined as:

where A is the cross-sectional area and P is the wetted perimeter. The wetted perimeter for a channel is the total perimeter of all channel walls that are in contact with the flow.[7] This means the length of the channel exposed to air is not included in the wetted perimeter.

For a circular pipe, the hydraulic diameter is exactly equal to the inside pipe diameter, as can be shown mathematically.

For an annular duct, such as the outer channel in a tube-in-tube heat exchanger, the hydraulic diameter can be shown algebraically to reduce to

where

is the inside diameter of the outside pipe, and

is the inside diameter of the outside pipe, and is the outside diameter of the inside pipe.

is the outside diameter of the inside pipe.

For calculations involving flow in non-circular ducts, the hydraulic diameter can be substituted for the diameter of a circular duct, with reasonable accuracy.

[edit] Flow in a wide duct

For a fluid moving between two plane parallel surfaces—where the width is much greater than the space between the plates—then the characteristic dimension is twice the distance between the plates.[8]

[edit] Flow in an open channel

For flow of liquid with a free surface, the hydraulic radius must be determined. This is the cross-sectional area of the channel divided by the wetted perimeter. For a semi-circular channel, it is half the radius. For a rectangular channel, the hydraulic radius is the cross-sectional area divided by the wetted perimeter. Some texts then use a characteristic dimension that is four times the hydraulic radius, chosen because it gives the same value of Re for the onset of turbulence as in pipe flow,[9] while others use the hydraulic radius as the characteristic length-scale with consequently different values of Re for transition and turbulent flow.

[edit] Object in a fluid

The Reynolds number for an object in a fluid, called the particle Reynolds number and often denoted Rep, is important when considering the nature of flow around that grain, whether or not vortex shedding will occur, and its fall velocity.

[edit] Sphere in a fluid

For a sphere in a fluid, the characteristic length-scale is the diameter of the sphere and the characteristic velocity is that of the sphere relative to the fluid some distance away from the sphere, such that the motion of the sphere does not disturb that reference parcel of fluid. The density and viscosity are those belonging to the fluid.[10] Note that purely laminar flow only exists up to Re = 0.1 under this definition.

Under the condition of low Re, the relationship between force and speed of motion is given by Stokes’ law.[11]

[edit] Oblong object in a fluid

The equation for an oblong object is identical to that of a sphere, with the object being approximated as an ellipsoid and the axis of length being chosen as the characteristic length scale. Such considerations are important in natural streams, for example, where there are few perfectly spherical grains. For grains in which measurement of each axis is impractical, sieve diameters are used instead as the characteristic particle length-scale. Both approximations alter the values of the critical Reynolds number.

[edit] Fall velocity

The particle Reynolds number is important in determining the fall velocity of a particle. When the particle Reynolds number indicates laminar flow, Stokes’ law can be used to calculate its fall velocity. When the particle Reynolds number indicates turbulent flow, a turbulent drag law must be constructed to model the appropriate settling velocity.

[edit] Packed bed

For fluid flow through a bed of approximately spherical particles of diameter D in contact, if the “voidage” is ε and the “superficial velocity” is V, the Reynolds number can be defined as:

Laminar conditions apply up to Re = 10, fully turbulent from 2000.[10]

[edit] Stirred vessel

In a cylindrical vessel stirred by a central rotating paddle, turbine or propeller, the characteristic dimension is the diameter of the agitator  . The velocity is

. The velocity is  where

where  is the rotational speed. Then the Reynolds number is:

is the rotational speed. Then the Reynolds number is:

The system is fully turbulent for values of Re above 10 000.[12]

[edit] Transition and turbulent flow

In boundary layer flow over a flat plate, experiments confirm that, after a certain length of flow, a laminar boundary layer will become unstable and turbulent. This instability occurs across different scales and with different fluids, usually when  ,[13] where

,[13] where  is the distance from the leading edge of the flat plate, and the flow velocity is the freestream velocity of the fluid outside the boundary layer.

is the distance from the leading edge of the flat plate, and the flow velocity is the freestream velocity of the fluid outside the boundary layer.

For flow in a pipe of diameter  , experimental observations show that for “fully developed” flow,[n 2] laminar flow occurs when

, experimental observations show that for “fully developed” flow,[n 2] laminar flow occurs when  and turbulent flow occurs when

and turbulent flow occurs when  .[14] In the interval between 2300 and 4000, laminar and turbulent flows are possible and are called “transition” flows, depending on other factors, such as pipe roughness and flow uniformity. This result is generalized to non-circular channels using the hydraulic diameter, allowing a transition Reynolds number to be calculated for other shapes of channel.

.[14] In the interval between 2300 and 4000, laminar and turbulent flows are possible and are called “transition” flows, depending on other factors, such as pipe roughness and flow uniformity. This result is generalized to non-circular channels using the hydraulic diameter, allowing a transition Reynolds number to be calculated for other shapes of channel.

These transition Reynolds numbers are also called critical Reynolds numbers, and were studied by Osborne Reynolds around 1895.[3]

[edit] Pipe friction

The Darcy–Weisbach friction factor f as a function of the Reynolds number and relative pipe roughness.

Pressure drops seen for fully developed flow of fluids through pipes can be predicted using the Darcy–Weisbach friction factor  against Reynolds number

against Reynolds number  and relative roughness

and relative roughness  . The diagram clearly shows the laminar, transition, and turbulent flow regimes as Reynolds number increases. The nature of pipe flow is strongly dependent on whether the flow is laminar or turbulent

. The diagram clearly shows the laminar, transition, and turbulent flow regimes as Reynolds number increases. The nature of pipe flow is strongly dependent on whether the flow is laminar or turbulent

[edit] Similarity of flows

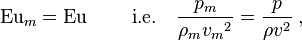

In order for two flows to be similar they must have the same geometry, and have equal Reynolds numbers and Euler numbers. When comparing fluid behavior at corresponding points in a model and a full-scale flow, the following holds:

quantities marked with ‘m’ concern the flow around the model and the others the actual flow. This allows engineers to perform experiments with reduced models in Froude number that governs open-channel flows. Some flows involve more dimensionless parameters than can be practically satisfied with the available apparatus and fluids, so one is forced to decide which parameters are most important. For experimental flow modeling to be useful, it requires a fair amount of experience and judgement of the engineer.

[edit] Smallest scales of turbulent motion

In a turbulent flow, there is a range of scales of the time-varying fluid motion. The size of the largest scales of fluid motion (sometimes called eddies) are set by the overall geometry of the flow. For instance, in an industrial smoke stack, the largest scales of fluid motion are as big as the diameter of the stack itself. The size of the smallest scales is set by the Reynolds number. As the Reynolds number increases, smaller and smaller scales of the flow are visible. In a smoke stack, the smoke may appear to have many very small velocity perturbations or eddies, in addition to large bulky eddies. In this sense, the Reynolds number is an indicator of the range of scales in the flow. The higher the Reynolds number, the greater the range of scales. The largest eddies will always be the same size; the smallest eddies are determined by the Reynolds number.

What is the explanation for this phenomenon? A large Reynolds number indicates that viscous forces are not important at large scales of the flow. With a strong predominance of inertial forces over viscous forces, the largest scales of fluid motion are undamped—there is not enough viscosity to dissipate their motions. The kinetic energy must “cascade” from these large scales to progressively smaller scales until a level is reached for which the scale is small enough for viscosity to become important (that is, viscous forces become of the order of inertial ones). It is at these small scales where the dissipation of energy by viscous action finally takes place. The Reynolds number indicates at what scale this viscous dissipation occurs.

[edit] In physiology

laminar flow. In turbulent flow the flow rate is proportional to the square root of the pressure gradient, as opposed to its direct proportionality to pressure gradient in laminar flow.

Using the definition of the Reynolds number we can see that a large diameter with rapid flow, where the density of the blood is high, tends towards turbulence. Rapid changes in vessel diameter may lead to turbulent flow, for instance when a narrower vessel widens to a larger one. Furthermore, a bulge of atheroma may be the cause of turbulent flow, where audible turbulence may be detected with a stethoscope.

[edit] In viscous fluids

Creeping flow past a sphere: streamlines, drag force Fd and force by gravity Fg.

Where the viscosity is naturally high, such as polymer solutions and polymer melts, flow is normally laminar. The Reynolds number is very small and terminal velocity quickly, from which the viscosity can be determined.

The laminar flow of polymer solutions is exploited by animals such as fish and dolphins, who exude viscous solutions from their skin to aid flow over their bodies while swimming. It has been used in yacht racing by owners who want to gain a speed advantage by pumping a polymer solution such as low molecular weight polyoxyethylene in water, over the wetted surface of the hull.

It is, however, a problem for mixing of polymers, because turbulence is needed to distribute fine filler (for example) through the material. Inventions such as the “cavity transfer mixer” have been developed to produce multiple folds into a moving melt so as to improve extruders to aid mixing.

[edit] Derivation

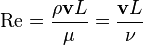

The Reynolds number can be obtained when one uses the Navier-Stokes equations:

Each term in the above equation has the units of a “body force” (force per unit volume) or, equivalently, an acceleration times a density. Each term is thus dependent on the exact measurements of a flow. When one renders the equation nondimensional, that is when we multiply it by a factor with inverse units of the base equation, we obtain a form which does not depend directly on the physical sizes. One possible way to obtain a nondimensional equation is to multiply the whole equation by the following factor:

where:

is the mean velocity,

is the mean velocity,  or

or  , relative to the fluid (m/s).

, relative to the fluid (m/s). is the characteristic length,

is the characteristic length,  , (m).

, (m). is the fluid density (kg/m³).

is the fluid density (kg/m³).

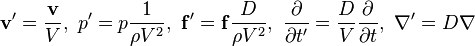

If we now set:

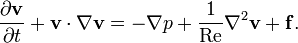

we can rewrite the Navier-Stokes equation without dimensions:

where the term

Finally, dropping the primes for ease of reading:

This is why mathematically all flows with the same Reynolds number are comparable. Notice also, in the above equation, as  the viscous terms vanish. Thus, high Reynolds number flows are approximately inviscid in the free-stream.

the viscous terms vanish. Thus, high Reynolds number flows are approximately inviscid in the free-stream.

[edit] See also

[edit] Notes

- ^ The definition of the Reynolds number is not to be confused with the Reynolds equation or lubrication equation.

- ^ Full development of the flow occurs as the flow enters the pipe, the boundary layer thickens and then stabilizes after several diameters distance into the pipe.

[edit] References

- ^ Stokes, George (1851). “On the Effect of the Internal Friction of Fluids on the Motion of Pendulums”. Transactions of the Cambridge Philosophical Society 9: 8–106. Bibcode 1851TCaPS…9….8S.

- 109431.

- ^ 10.1146/annurev.fl.22.010190.000245.

- ^ Reynolds Number

- ^ Batchelor, G. K. (1967). An Introduction to Fluid Dynamics. Cambridge University Press. pp. 211–215.

- ^ Reynolds Number Engineeringtoolbox.com

- full citation needed]

- 0-471-20231-2.

- ^ Streeter, V. L. (1962). Fluid Mechanics (3rd ed.). McGraw-Hill.

- ^ http://books.google.com/books?id=P9Qgvh7kMP8C&pg=PA29.

- 978-0-674-03116-6.

- 0-7506-6538-6.

- ^ De Witt, D. P. (1990). Fundamentals of Heat and Mass Transfer. New York: Wiley.

- ^ Holman, J. P. (2002). Heat Transfer. McGraw-Hill. p. 207.

[edit] Further reading

- Zagarola, M.V. and Smits, A.J., “Experiments in High Reynolds Number Turbulent Pipe Flow.” AIAApaper #96-0654, 34th AIAA Aerospace Sciences Meeting, Reno, Nevada, January 15–18, 1996.

- Jermy M., “Fluid Mechanics A Course Reader,” Mechanical Engineering Dept., University of Canterbury, 2005, pp. d5.10.

- Hughes, Roger “Civil Engineering Hydraulics,” Civil and Environmental Dept., University of Melbourne 1997, pp. 107–152

- Fouz, Infaz “Fluid Mechanics,” Mechanical Engineering Dept., University of Oxford, 2001, pp96

- E.M. Purcell. “Life at Low Reynolds Number”, American Journal of Physics vol 45, p. 3-11 (1977)[1]

- Truskey, G.A., Yuan, F, Katz, D.F. (2004). Transport Phenomena in Biological Systems Prentice Hall, pp. 7. ISBN 978-0-13-042204-0.

[edit] External links

- Gas Dynamics Toolbox Calculate Reynolds number for mixtures of gases using VHS model

- Browser-based Reynolds number calculator.

- University of Nottingham video about the Reynolds number

Source: Wikipedia

is the mean velocity of the object relative to the fluid (

is the mean velocity of the object relative to the fluid ( is a characteristic linear dimension, (travelled length of the fluid;

is a characteristic linear dimension, (travelled length of the fluid;  is the

is the  is the

is the  ) (m²/s)

) (m²/s) is the

is the

is the

is the  is the volumetric

is the volumetric  is the pipe cross-sectional area (m²).

is the pipe cross-sectional area (m²). is the

is the  (m²/s).

(m²/s).

is the inside diameter of the outside pipe, and

is the inside diameter of the outside pipe, and is the outside diameter of the inside pipe.

is the outside diameter of the inside pipe.

is the mean velocity,

is the mean velocity,  or

or  , relative to the fluid (m/s).

, relative to the fluid (m/s). is the characteristic length,

is the characteristic length,  , (m).

, (m). is the fluid density (kg/m³).

is the fluid density (kg/m³).